DON’T DIG YOURSELF INTO A HOLE: CHOOSING THE RIGHT TRELLISING PRODUCTS FOR YOUR VINEYARD

During May you might have planted new vines for future production, whether expanding an existing vineyard or starting from scratch. Now that the busy time of planting is over you’ll be turning your mind to implementing trellis systems to support these young vines. Previously we have discussed the merits of galvanising, and the materials used in the construction of posts we use in vineyards today. But what of the rest of the trellis system; which material do you need and what about installation…?

Let’s start with the soil: when it comes to trellising, soil is everything and will determine much of your decision-making. The most important structural element of the trellis system is the anchor and end post assembly. If your topsoil is shallow with a solid subsoil of chalk or sandstone, or contains high levels of flint or alluvial stone, your anchor must be able to penetrate through or between the rock with minimal disturbance and effort. Typically, this will be a Gripple 3 or a Platipus style anchor with a smaller head. For heavier, deeper more clay-based soils a screw anchor or larger Gripple 4 anchor will be more suitable, its larger head creating greater soil resistance. All anchors should be designed to last by galvanising with a zinc-aluminium alloy, and with the correct drive rod or bar can easily be installed by hand or machine. Never install using a pre-drilled pilot hole as this undermines the integrity of the hole and therefore the load capacity of the anchor. While it may seem quicker and easier to do it this way it will quickly lead to problems. Always use the correct tools for the job and if you can’t access them use a contractor who can.

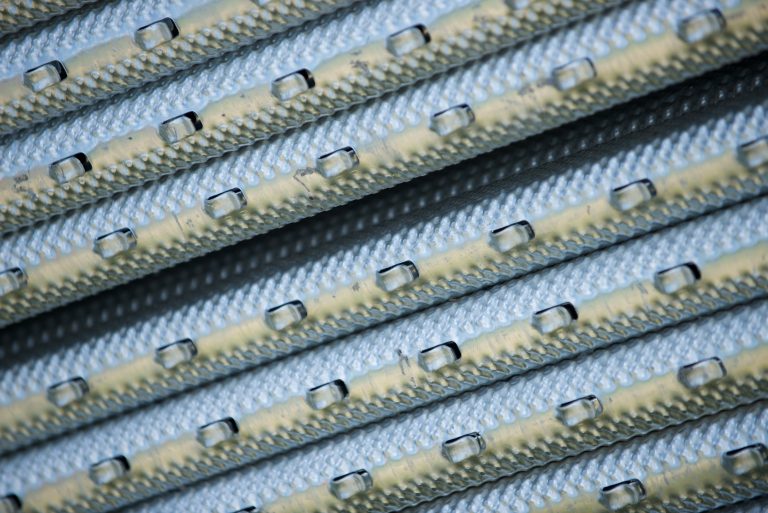

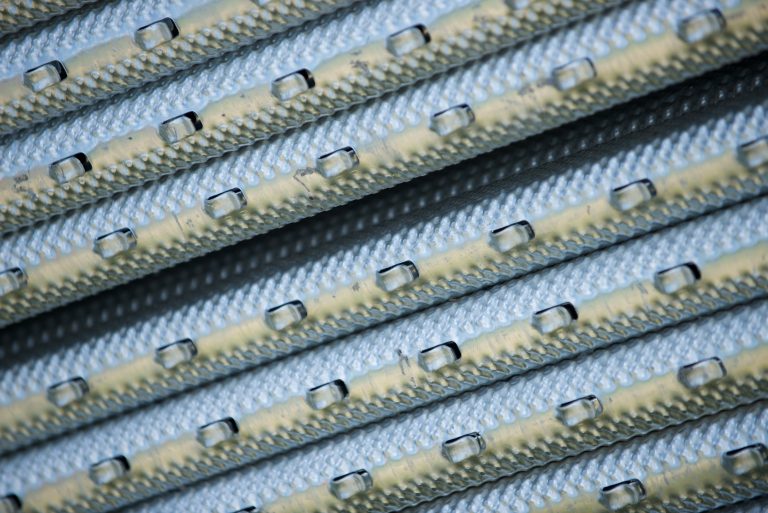

Anchors are secured to the end post using a galvanised cable, most commonly the Gripple GPak3 cable, again made from a zinc-aluminium alloy which comes with a gripple tensioner allowing you to tension as required. For fruiting and foliage wires the use of non-galvanised product is to be avoided. When the canopy is at full height and weight the wires form an integral part of the structure and need to be galvanised, and of suitable strength and thickness. There are synthetic wires available but, although cheap, flexible and lightweight, these are easily breakable and lack the loading capacity that metal wires provide. When considering your wire there are two main categories: fruiting and foliage. Fruiting wire sits roughly 0.9m -1m above the ground and is recommended to be a minimum of 2.5mm thick to provide a strong base for the cane to be tied to. Foliage wire, of which there are typically three pairs, needs to be 2.0mm in thickness to provide both strength and flexibility to lift the wire around the canopy. Foliage wires are attached to the end post by a chain and a hanger which allow movement up and down the tags on the end post, as well as adjusting the tension through the links in the chain. As with all materials these must be galvanised to ensure durability.

Using the best materials does not guarantee a quality trellis system – installation is key. While making the job easier in tougher ground, the drilling of pilot holes leads to loose soil surrounding the post or anchor; constant repair of wonky posts and a system unable to support the weight of canopy and your bountiful fruit.

There are several pieces of kit available, from hand held post knockers and vibrational rammers to tractor mounted versions. Vibrational rammers are better than conventional fence post rammers as they work by pushing the post into the ground, reducing the damage done to flayed post ends. When meeting resistance a vibrational function drives the post to the desired depth, in the case of a 2.5m intermediate post this is 0.7m and a 2.75m end this is 0.85m. This finish gives you a sound installation with maximum integrity, piercing both the top and sub soil with minimal disturbance.

With the intention of having the system, posts and anchors in the ground for 25+ years it is common sense to use the correct materials and tools, and to install it right the first time around. Don’t dig yourself into an unnecessary hole, you will come to regret it!